2000 Yamaha GPR

"Vigilante"- ENGINE, ELECTRONICS,

FUEL, COOLING

If you have interest in sponsoring this project,

with either parts or discounts, please email me at hydrotoys@yahoo.com

Intake System: I'd prefer a 4"

system with the flame arrester buried up inside a splash proof area of

the steering. I have a 3 to 4 reducer off of ebay. This will be one of

the last things to get built.

-

3" to 4" elbow for Air intake.

-

3" Air Intake System.

-

RXP 3" Riva air intake fits the GPR perfectly.

-

I'll use this until testing done.

-

-

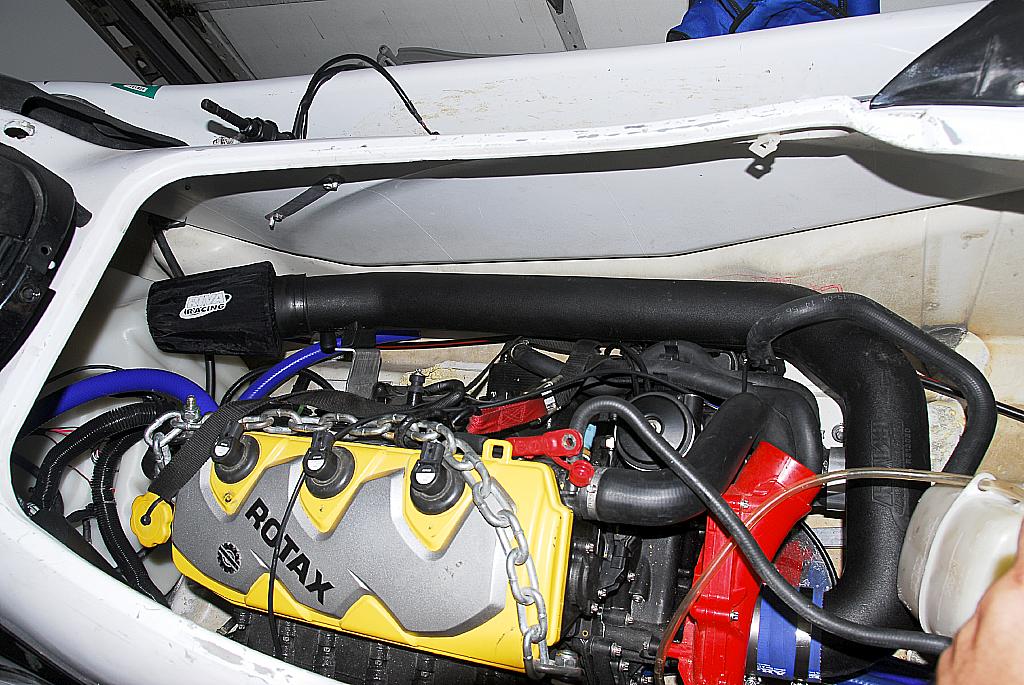

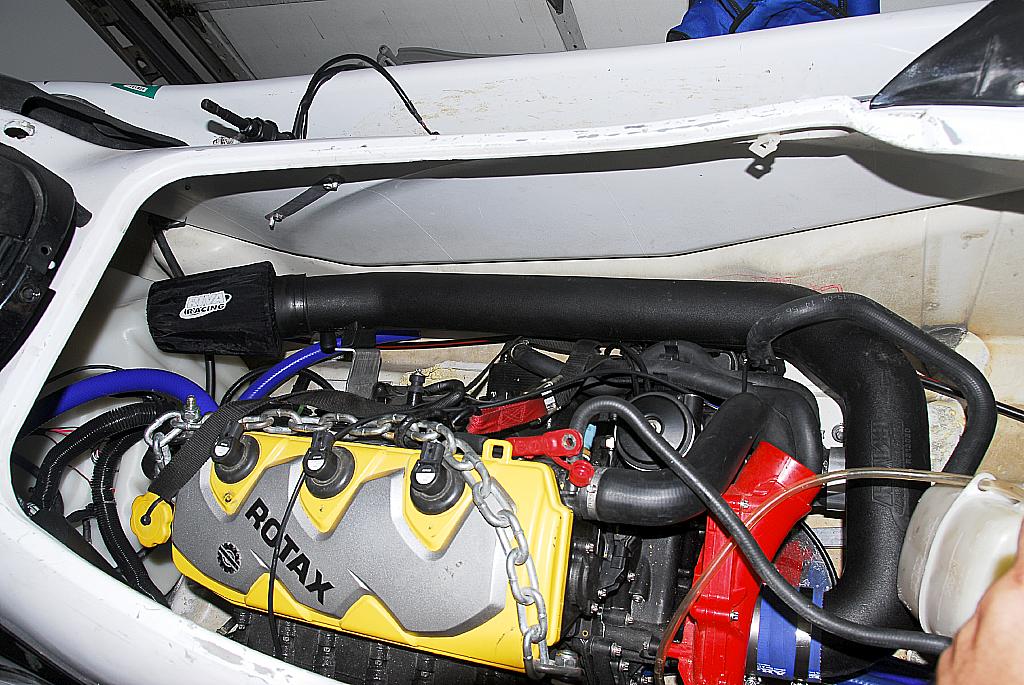

Electronics and Electrical:

Game plan here is to use the entire RXP wiring harness. The heavier than

stock AGM battery is relocated behind the gas tank. I am utilizing

a permanent boost gauge for monitoring the flaky supercharger clutch system.

An Autometer liquid filled temp gauge is permanently mounted on the right

side to seperately monitor the closed loop cooling at the heat exchanger.

The speed/water temp monitor will be mounted on the rideplate with a bracket.

The air temp sensor is mounted to a wiring harness under the dash. The

trim system will need to be reprogrammed to not error out, or install it,

if it will fit. The RXP gauge package is larger (and much nicer) than the

GPR system. With a mode control, large readouts and very friendly digital/analog

system, I mounted it on the MUCH smaller gpr dash. The electronics distribution

center was mounted port side, up front. It is riveted to the wall of the

inner liner.

Boost Pressure Gauge.

-

Radiator Temp Gauge.

-

-

AGM Battery and relocation.

-

-

Gauge Package modification to GPR dash.

-

-

-

Electronics Distribution center location.

-

-

Wiring/Hull Block Diagram.

-

Speed and Water Temp Sensor Relocation.

-

Cooling System: The stock Rotax

system is an automotive style closed loop system, utilizing the rideplate

as a radiator. While very innovative, it is very limiting. In the GPR,

I'm looking at two different systems to try. The first way utilizes the

stock closed loop system, and replaces the rxp rideplate with a 80,000

btu water/water heat exchanger. The open loop cooling will cool the heat

exchanger, which in turn cools the closed loop Rotax system. Obviously

the other model to use would be an after market open loop panel, and cool

the engine similar to a stock gpr. Light, and less parts, this may be the

way to go. I will use 5/8" water lines from the pump... the largest I've

ever used on a gpr to try and build pressure and volume within this massive

unit.

The "other" cooling system, is a

standard open loop lake water system to cool the intercooler, and pipe

jacket. This is regulated by an orifice to control flow/pressure to around

38 psi at WOT. Eventually, I'll look into separating these two systems

so that cooling water can be increased to the intercooler, without affecting

the exhaust loop. The exhaust loop is purposefully kept very, very warm.

-

Heat Exchanger and fittings. AN12 fittings for the open loop, and 3/4"

NPT fittings used for the closed loop 1" lines..

-

-

Metal shelf made to hold heat exchanger.

-

-

Double single cooling block with 3/8" line and 5/8" line.

-

2 separate 1/2" water dumps with internal restrictors to control pressure.

-

1" closed loop lines.

-

-

Stock RXP Cooling bottle mounted on battery box.

-

-

Riva 165 deg thermostat mod.

-

-

Open Loop system diagram for Closed Loop cooling.

-

Open Loop system for specifically cooling exhaust.

-

Exhaust System: The RXP waterbox

sits at a near 30 deg angle to the engine and driveline, which means the

"J-pipe" between the manifold and waterbox is very short. Instead

a Rotax Racing Waterbox was adapted. A modified Rotax Racing "through-hull"

pipe was mated to the stock GPR exhaust outlet.

-

GPR/RXP waterbox placement.

-

-

Rotax Racing water box. Stock GPR strap. Hump-Hose Coupler and 2.5" coupler

by Stylin-Motors Paint is Rustoleum Hammer Paint, Stock RXP sensor.

-

-

Waterbox mounting and strap.

-

-

Rotax Racing Pipe mated to the GPR exhaust and RR waterbox.

-

-

Stock J-pipe, cut per Rotax Racing instructions.

-

-

GP12r Fuel Tank Modification: The XLT

utilizes an 18 gallon fuel tank. I had hoped to install this in the gpr

however, the RXP fuel pump is too shallow to sit flush against the bottom

of the 18 gallon tank. I'm not sure if this is a problem or not, but I'm

not willing to introduce more problems at this time so I'm sticking with

the rxp tank.

-

Rxp tank. Fits right in. In fact backwards it almost lines up with the

filler.

-

-

Vent lines for the gas tank will utilize the stock gpr water pissers on

the sides of the hull.

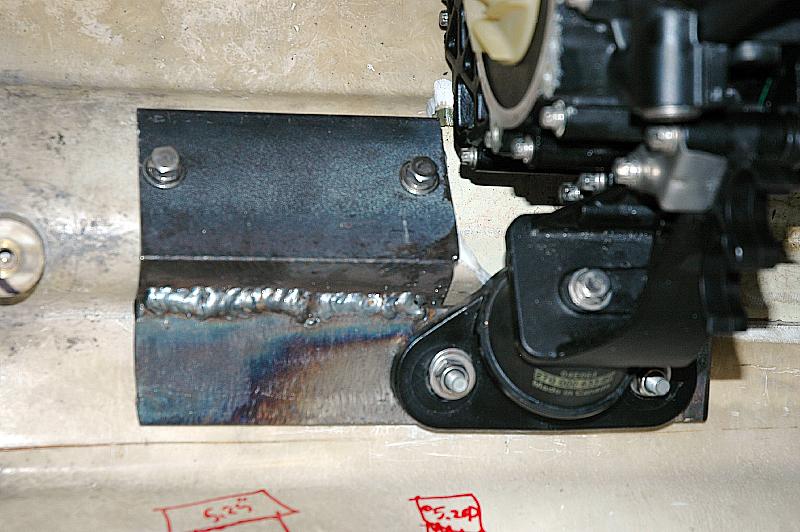

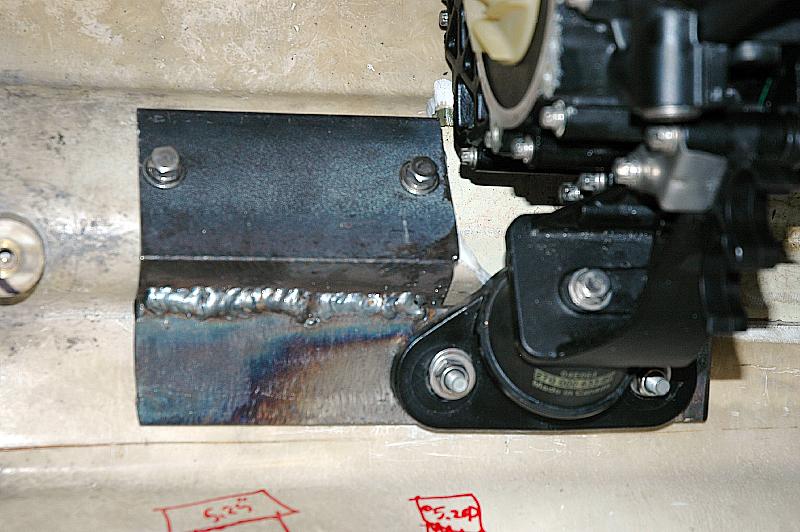

Motor Mount System:

The gpr uses a four point non-symetrical mount system with round retarded

non-parallel runners from front to back. They are even a different height

from each other... lovely. The rotax uses a 3-point symmetrical system.

The gpr hull depth is close to 1" more shallow than the RXP which requires

some inner hull trimming. The Rotax oil cooler hits the starboard stringer.

In fact most of the engine hits the starboard stringer. The mount system

is a tad bit short to clear the engine length. The starboard mount was

moved back nearly 4" to clear the block. All of this, was to get a clean

alignment for the drive shaft, as well as retain a weight distribution

near the gpr, if not a few inches aft. The holes in the inner liner will

be filled with a combonation of carbon fiber, fiberglass, and hole filler.

Eventually, the mount system will be integrated into the hull for rigidity.

-

All three mounts in place, and ready for fiberglass repair to the inner

deck. A starboard rear mount will be redesigned to be glassed in after

performance shakedown testing.

-

-

Front mount system mock up.

-

-

This will eventually be made of aluminum.

-

This accepts standard rxp shims..

-

Relationship between engine, waterbox, SC, Riva thermostat, and 2002

driveshaft. The longer driveshaft is used for the 2" extended pump.

-

-

Rotax Racing Front Engine mount.

-

-

This will prevent engine flexing. Very nice unit!!!

-

Rear Port mount relocation.

-

-

This was a very straightforward design, utilizing 2 flat 3/8" plate and

a straight weld

-

This will eventually be aluminum.

-

This accepts stock RXP engine shims..

-

Rear Starboard mount relocation.

-

-

Mount moved rearward approx. 4" to clear engine block.

-

2.5" x 1/4" angle iron and flat plate welded together to create a very

strong vertical mount with the stock stringer.

-

This accepts standard RXP spacing shims, but the mount must be removed

to install them.

-

This will eventually be Stainless instead of aluminum due to bending concerns.

-

Starboard Stringer Removal.

-

-

Inner liner removal and reshaping.

Driveshaft coupler modification: The

driveshaft system on the GPR uses a pretty standard rubber biscuit and

bearing feed through. The RXP uses a type of feed through designed by cavemen

and a doughnut. It utilized a crowned driveshaft to offset mis-alignment,

with a hard floating seal that trys to destroy itself. There is no mid

shaft support. It's all driven off of the engine and the pump. Very stupid

sloppy design with built in failure. Popular discussions on the forums

are how to repair it. Rotax Racing offers a two piece design, but it is

too long for my application, and the rear driveshaft is not needed. A local

spline company is designing a splined intermediate shaft adapter as well

as modifying the RXP driveshaft to fit it, so that I can continue to use

the stock gpr driveshafts and shaft bearing supports.

Base

Craft

Base

Craft

Donor Craft

Donor Craft

Hull,

Steering,Pump, Prop, Intake, Rideplate, Grate/shoe

Hull,

Steering,Pump, Prop, Intake, Rideplate, Grate/shoe

Vigilante

Home Page

Vigilante

Home Page

Cost,

and Sponsors

Cost,

and Sponsors

Modification

List

Modification

List

Performance

Page

Performance

Page

Marks

Page

Marks

Page

TUNERS:

The information presented here

reflects solely our personal experience with our own personal power toys

(motorcycles, atv's, watercraft) and is presented for entertainment purposes

only. No information presented here is to be relied upon for issues of

rider safety nor to replace the services of a qualified service technician.

Any attempts to follow or duplicate any of these procedures are done

so completely at your own risk. By reading the information on this site,

you agree to assume complete responsibility for any and all actual

or consequential damages that may arise from any information presented

herein.

TUNERS:

The information presented here

reflects solely our personal experience with our own personal power toys

(motorcycles, atv's, watercraft) and is presented for entertainment purposes

only. No information presented here is to be relied upon for issues of

rider safety nor to replace the services of a qualified service technician.

Any attempts to follow or duplicate any of these procedures are done

so completely at your own risk. By reading the information on this site,

you agree to assume complete responsibility for any and all actual

or consequential damages that may arise from any information presented

herein.

Base

Craft

Base

Craft

Donor Craft

Donor Craft

Hull,

Steering,Pump, Prop, Intake, Rideplate, Grate/shoe

Hull,

Steering,Pump, Prop, Intake, Rideplate, Grate/shoe

Vigilante

Home Page

Vigilante

Home Page

Cost,

and Sponsors

Cost,

and Sponsors

Modification

List

Modification

List

Performance

Page

Performance

Page

Marks

Page

Marks

Page

TUNERS:

TUNERS: